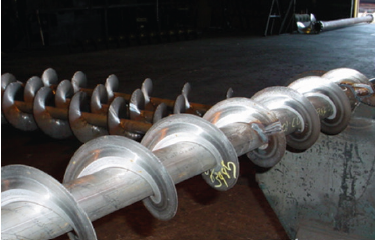

Matthiesen Screw Conveyor Systems

Increase productivity with the customizable Matthiesen Screw Conveyor System. These systems can be custom fabricated to fit any configuration at your facility, with options that include: jailbars, downspouts, inclines, variable pitches, liners, portability, and many more.

- All trough joints have gaskets

- Dodge drives are standard: using v-belts, pulleys and sheaves for ease of changing RPMs

- Electrical, motor size, RPM all as requested (all motors are TEFC – washdown available)

- All UHMW is FDA approved

Matthiesen utilizes 304 stainless steel standard for all screw conveyors, however, additional finishing is needed to meet food grade requirements. For an auger to be 100% food grade, it would have no liner, no hangers, no shroud cover, fully welded seams, and a polished finish. The conveyor stands would need to have welded caps instead of open ends.

Matthiesen offers options to meet your food grade needs:

- Glass bead blasting

- Fully-welded seams only

- Glass bead blasting and fully-welded seams

- Food grade surface polish on the auger and fully welded seams (polish replaces need for glass bead sanding)

- Capped stands

Matthiesen is a manufacturing company proud of its past, working hard for you today and focused on the future. They are dedicated to producing the highest quality packaging and handling equipment.

Modern Ice and our Freeze Force Technical Services Team engineer, design, and integrate Matthiesen’s equipment into your plant. This strategic partnership can help you achieve the goals you have for your business.