Need Quality Ice Bags? Here's Why:

Modern Ice Equipment & Supply

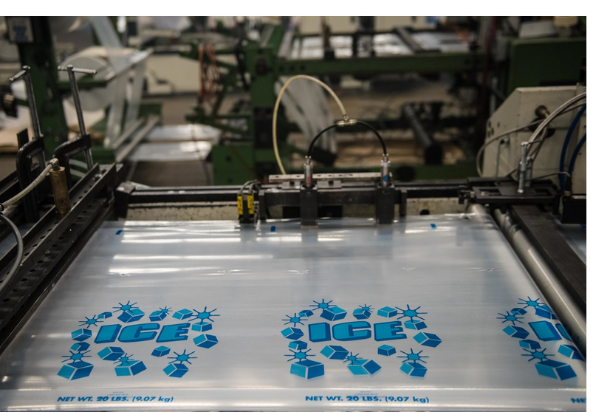

When you think about your bag of ice, you might not give much thought to the bag itself. After all, it’s the ice inside that counts, right? Well, yes and no. The truth is, the bag plays a vital role in ensuring that the ice you receive is of the highest quality, and here’s why it matters.

Bag Terminology:

Preformed Bag: a bag that is already sealed on three sides and is ready for ice immediately.

Wicket Bag: bags that are placed on wickets, two metal rods, in order to run properly on the machine.

Reverse Wicket Bag: bags that are placed on wickets, two metal rods, backwards in order to run properly on the machine.

Roll Stock Bag: these bags are not preformed, instead they come on a roll and the machine cuts and seals the bags as it goes.

Bailer Bag: large bags that hold multiple smaller bags of ice.

Gusset: the folded portion on the bottom of the bag that unfolds when ice is put in to make the bottom of the bag flat.

Lip: the area between the top of the bag and the top of the handle.

I-Mark: the I-mark is essential to determining where the machine cuts the bags and seals them.

Resin: the key component that makes up the polyethylene film that bags are made of.

Share:

Social Media:

Most Popular:

Screw vs. Recip Compressor

Commercial Application : Expand Your Cold Storage

Modern Ice University Class

Packaged Ice Announcement- B&P Pricing Announcement

Subscribe To Our Weekly Newsletter

Categories

Related Posts

Screw vs. Recip Compressor

Screw vs. Reciprocating Compressors Modern Ice Equipment & Supply The Decision That Impacts Your Production, Efficiency, and Peak Season Reliability. The wrong compressor decision doesn’t

Commercial Application : Expand Your Cold Storage

Case Study: Expanding Cold Storage with Custom Leer Walk-In Cooler Modern Ice Equipment & Supply DDA Oil, Inc. Owner, Pawan, partnered with Modern Ice to

Modern Ice University Class

Modern Ice University Form Fill Seal Training & Hamer 125 Rebuild Class Recently, we welcomed customers to Greendale, Indiana for another Modern Ice University (MIU)