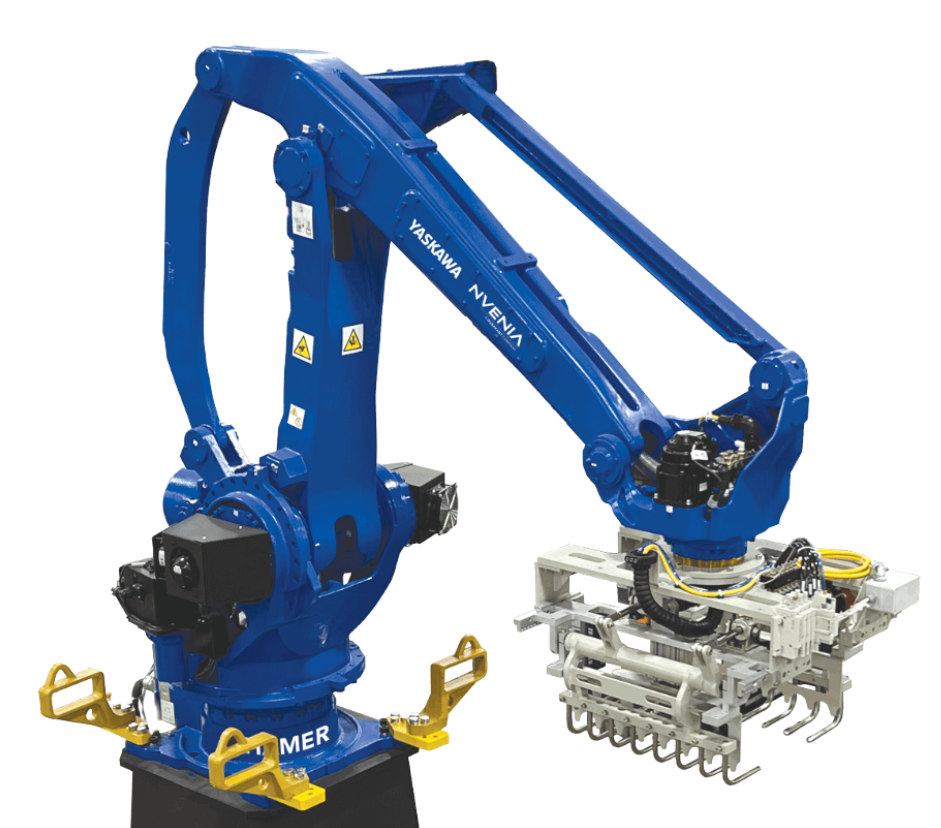

Hamer Robotic Palletizer

Modern Ice introduced palletizing to the ice industry almost 20 years ago. The technology and efficiency has come a long way since then! Modern Ice teams with nVenia (formerly Hamer-Fischbein) to offer you the Hamer Automatic Ice Palletizer designed to be integrated with the leading packaging equipment in the Packaged Ice industry.

This system offers flexibility to manage large and small bags, varying space requirements, multiple speed requirements, and most importantly has the quality of Hamer and Modern Ice backing it up.

The Hamer Automatic Ice Palletizer is an automated ice packaging system that was made to increase efficiency and productivity in the packaged ice industry.

From semi-automatic (just palletizes; you manually set and remove pallets) to fully-automatic (pallet dispenser, slip sheet dispenser, stretch wrapper, etc.), the Hamer Automatic Ice Palletizer can be configured to meet your plant’s specific needs.

-Reduces labor costs

-Available in semi- or fully-automatic

-Increase productivity and consistency of pallets

-Programmable / Selectable Pallet Patterns

-Fast Palletizing Rates

-Custom designs available for small footprint systems

-Integrates with other packaging equipment

-Yaskawa / Motoman4-6 Axis Servo Industrial Robot

-DX200 Robot Control Panel

-Robot Mounting Base

-Robot Teach Pendant

-Industry Standard Wire Mesh Safety Guarding with Interlock Access Door

-Semi-auto; up to 40 Bags per Minute*

-Single Pick, Fully Automatic; Up to 24 Bags per Minute*

-Multiple Pick, Fully Automatic; Up to 40 Bags per Minute*

-320-Pound (160 kg) Capacity Robot Arm

-Robot Mounting Base

-Robot Teaching Pendant

-Industry-Standard Wire Mesh Safety Cage

*Rates are pallet design/case/bag size dependent

-Allen Bradley PLC with Touchscreen

-Hamer EasyPic Operator HMI

-Fully Automatic or Semi-automatic Systems

-Multiple Robot Arm Systems

-NEMA 4X Controls and Robot Protection Packages for Corrosive Environments

-Access to Full Line of Yaskawa/Motoman Robots for Custom Solutions

-Corrosion Resistant Packages for Conveyors, Robot Arm, and Controls

-Various Power Options

-Custom Conveying for Bag, Case, Bucket/Pails, Conditioning,

-In-feed, Pacing, Picking, Power Curves, and Accumulating

-Automatic Pallet Dispenser

-Automatic Slip Sheet Dispenser

-CDLR Full Pallet Conveyors

-90-Degree Full Pallet Transfer

-Quad Muting Light Curtains for Continuous Operation (Semi Automatic)

-Integrated Automatic Stretch Wrapper or Manual Bagging Systems

-Automated, Semi-Automated or Manual Bagging Systems

-Multiple Pick Points

-Multiple Stack Points

End of Arm Tooling:

-Bag Clamp, Single or Multiple Pick

-Bag Clamp, Fixed Size; Manually Adjustable or Servo/Automatically Adjustable

-Case Grip; Single or Multiple Pick

-Fork Style; Multiple Pick

-Vacuum; Single or Multiple Pick

Multi-function End of Arm Tooling:

-Pallet Pick/Place

-Slip-sheet Pick/Place

-Auto Tool Change

-Auto Height Sensor

Modern Ice partners with nVenia because of their commitment to history within the packaged ice industry. The combination of the Modern Ice and nVenia teams can provide clients with a complete packaging solution for their ice plant and the knowledge and experience required to train clients on the equipment to ensure it operates as efficiently as possible.