Hamer Model 5525X Enhancements:

- Powered Pinch Roll Film Unwind - Reduces film tension variability, improving side seal quality and ensuring a steady bagging rate.

- Servo Volumetric Filler - Allows tool-free ice weight adjustments during bagging for seamless, on-the-fly changes.

- Cut and Clamp Side Seal - Offers improved temperature control and quicker heat-up, with a user-friendly, easy to set-up design.

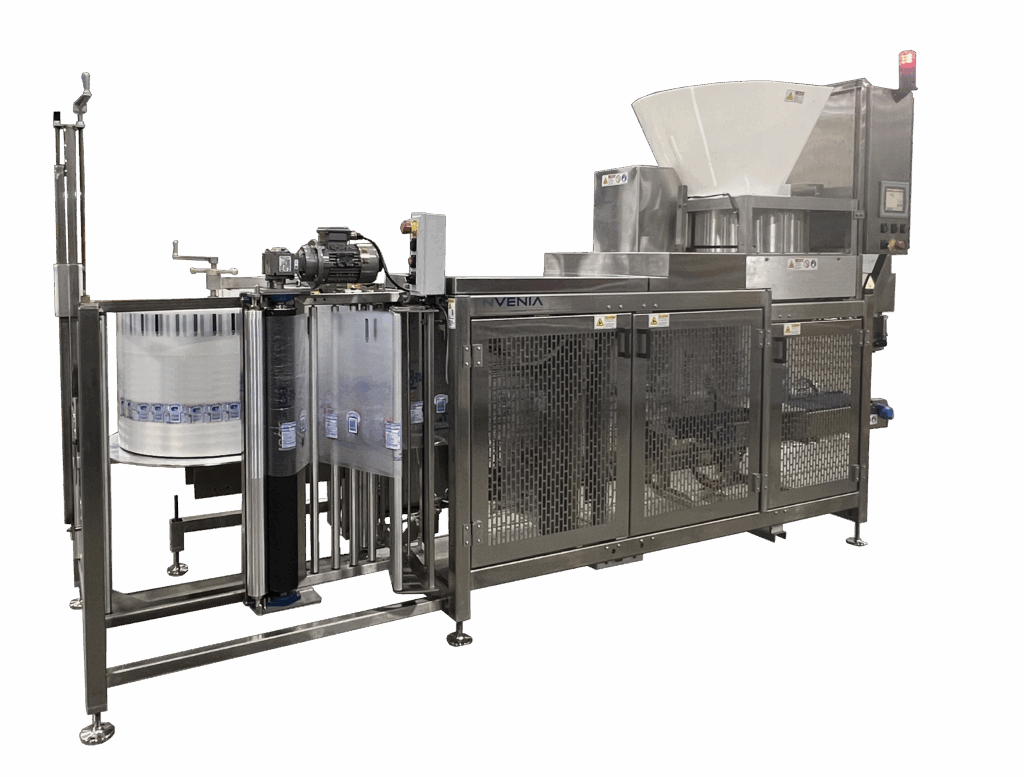

Hamer Model 5525X FFS Automatic Ice Bagger – Form, Fill, & Seal

The all-new Ice X Platform combines the proven reliability you trust with design improvements that boost performance, enhance product quality, and reduce maintenance, keeping your operations running smoother than ever.

The first model in this platform, the HAMER Brand Model 5525X ice bagging machine, has been completely re-engineered from the ground up, incorporating proven technologies for superior performance and flexibility. This high-speed, automated system efficiently packages ice in bag sizes from 5 to 25 lbs. on a single machine. For precise, high-speed dosing, the 5525X includes an optional servo-driven volumetric filler, easily adjustable through the HMI, along with a reliable wire tie closure for secure bag sealing.

Standard Features:

– Constant tension film dancer arm eliminates intermittent

motion of film feeding for smooth control

-Servo Driven Film Path – minimizes variation in film tension thru controlled acceleration and deceleration of the film pull

-Clamp and cut side seal provides a superior seal on every bag

-Stainless steel and/or “lube for life” bearings reduce

maintenance costs

-Adjustable belt speed from the HMI allows for more precise control

– Self-tracking, modular plastic chain conveyor provides positive drive

and less maintenance

– Bag cost savings of up to 20% and less storage space with pre-printed, center-fold poly film compared to pre-made open mouth bags

-Corrosion-resistant, stainless steel, heavy-duty construction for ease of cleaning and long-lasting, trouble-free service

-Compact design accommodates system location in low-overhead

areas under existing equipment

-Horizontal, compact design accommodates system location in low-overhead areas under existing equipment

-Integrated machine mounted 20” roll holder with option for 35” roll holder increases uptime by limiting need to change film during

long product runs

-Crank adjustment conveyor easily accommodates different bag sizes

-Allen Bradley® CompactLogix PLC with intuitive HMI for simple machine operation

-Easily switch HMI menu language between English and Spanish

-10 built-in bag recipes for quick setup and changeover

Specifications:

-Dimensions: 123”L x 41”W x 84”H

-Clearance: 3 ft. clearance recommended all sides

-Capacity: Bag Sizes 9” to 16” wide, 16” to 35” long

-Poly Thickness 1.5 mil to 4 mil

-Voltage: 230V, 3ph, 60 Hz, 29 FLA

-Air requirements: 12 CFM @ 80 PSI

-Speed: Up to 55 bags/minute

Options:

-HAMER Model 125 Wire Tie Bag Closer with hardware electrics; available in 16-gauge or 17/18-gauge options

-Gusset former

-Single-hole punch

-Integrated machine mounted 35” roll holder

-Core lift chuck for 35” rolls

-Pneumatic core chuck

-Inkjet date coder for automatic imprinting of date/shift code on bags

-Embossing coder – 4 or 8 character

-Caster kit

-3 lb bag

Modern Ice partners with nVenia because of their commitment to history within the packaged ice industry. The combination of the Modern Ice and nVenia teams can provide clients with a complete packaging solution for their ice plant and the knowledge and experience required to train clients on the equipment to ensure it operates as efficiently as possible.